Do you know IoT implementation in the logistics inventory is making revolutionary changes? The critical elements that need continuous monitoring such as inventory count, returns management, temperature regulation of certain products, and more are easily managed with IoT-based inventory management systems.

Inventory management using IoT is an effective way for businesses to streamline their operations. Existing manual systems have many drawbacks, including the high risk of human errors. To get over it, consider using IoT-based systems. Moreover, Markets and Markets forecasts that industrial IoT will grow from $76.6 billion in 2021 to $106.1 billion by 2026. This growth makes today the best time for you to invest in technological advancement for your business. Continue reading this blog to know why IoT-based systems are an excellent choice for your business.

All About IoT-based inventory management

In inventory management, firstly, the inventory is received at the warehouse, and the data is entered into the database. Next, they are moved and stored to their designated locations across multiple warehouses. Then, they are accessed when order arrives. Certain products which are temperature sensitive are monitored frequently. All these when managed with traditional inventory management method can lead to inaccuracy. Hence, IoT-based systems are adapted.

Internet of Things (IoT) is the network of physical devices embedded with electronics and network connectivity to identify, collect, and exchange data. The IoT-based system allows different objects to connect and transfer data rapidly, securely, and effectively with artificial intelligence (AI) and machine learning (ML).

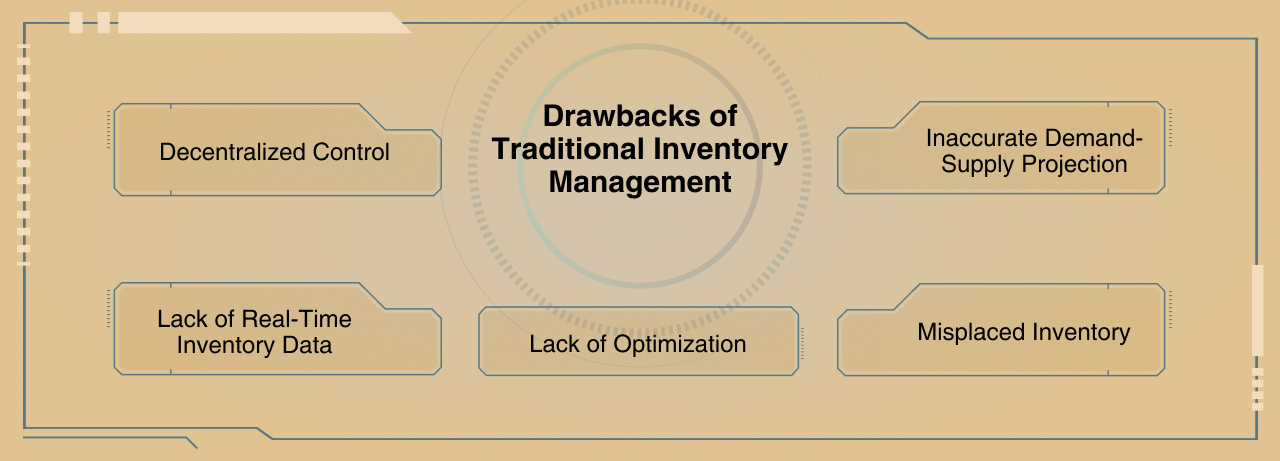

Drawbacks of Traditional Inventory Management

Drawbacks of Traditional Inventory Management

-

Lack of real-time inventory data

When you manually enter data to keep track of inventory, you would never have accurate data. For example, you shipped the last available piece of a product and forgot to update the inventory accounts. Next time, when an order arrives, your staff won’t be able to figure out if the product is available or not. Hence, with traditional systems, it becomes difficult to keep inventory accounts up to date. -

Inaccuracy in demand and supply projection

With traditional systems, inventory optimization is back-breaking; it is difficult to fill the gap between the inventory and the demand. Moreover, it becomes complicated to streamline data for future prediction and trend analysis. -

Decentralized control

For businesses to stay profitable, it is essential to adopt a centralized approach. However, when you use a traditional system, the information is updated periodically, which leads to a decentralized approach. -

Lack of optimization

Manual inventory management has limited growth opportunities, and as your business expands, so will the inventory. This leads to an increase in demand for staffing, which can be inefficient and inaccurate. Hence, it is laborious to optimize inventory accounts with traditional systems. -

Misplaced Inventory

When the manual systems are in place, you have to keep a tab on inventory manually. This is a waste of time and increases your labor costs. Moreover, it is easy to misplace inventory under these circumstances.

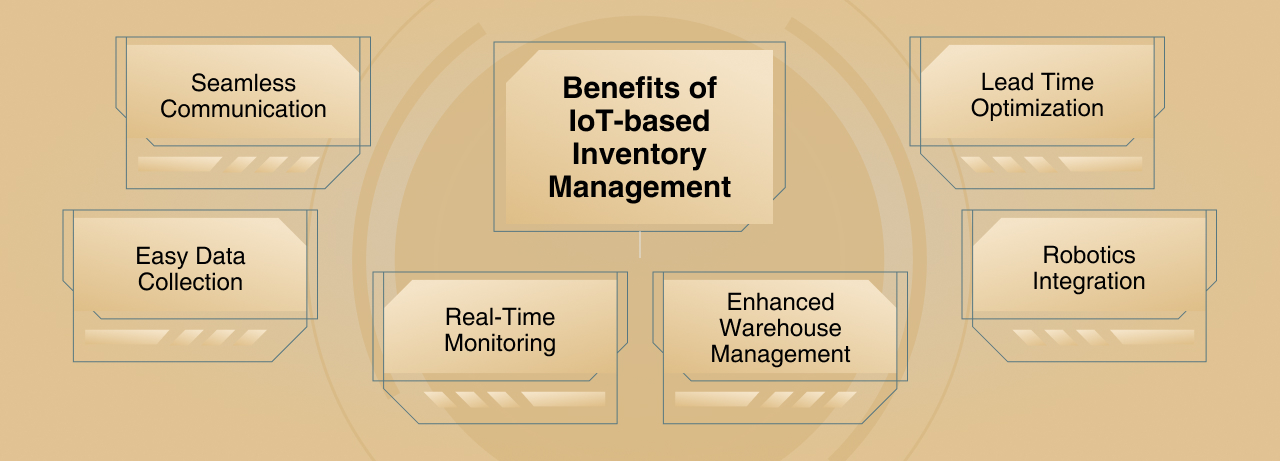

Benefits of IoT-based Inventory Management

Due to the many disadvantages of traditional systems, IoT-based systems have become popular among businesses. IoT systems are optimized and they improve the ability to view, track, and monitor inventory. Besides, the data fetched by IoT systems are available to you in the form of meaningful insights.

The output of IoT systems can be of various forms; it can alert if an item is lost, generate orders when reorder point is hit, predict future inventory needs, notify in case of overstocking, provide inventory location, and more. With automated systems, it becomes easy to optimize inventory management and adapt a centralized approach.

IoT-based systems lay a foundation for a digitized approach. It has many benefits, including:

-

Seamless Communication

IoT inventory systems use radio-frequency identification (RFID) to update data in real-time. By connecting sensors with RFID tags, the devices can easily communicate and transmit data. -

Real-time monitoring

Real-time tracking of your inventory becomes easy with IoT systems. You can know the exact location of each item at any time among multiple warehouses. -

Easy Data Collection

With real-time data collection, it becomes easy to record and check the status of each item. Automated systems reduce errors and inaccuracies and provide up-to-date information every time without human intervention. -

Enhanced Warehouse Management

IoT inventory optimization improves warehouse management and logistics. Along with managing and updating inventory in the database, it analyzes the sale patterns and provides insights for forecasting product demands. Moreover, it tells us how long a product is on the shelf and prevents overstocking. -

Lead time optimization

IoT based inventory management solutions allow manufacturers to reduce lead time. This is possible due to real-time data and analytics-based foresight. -

Robotics Integration

Implementation of IoT systems leads to faster and better operations. In addition, ML integration with these systems helps automate various tasks like picking, scanning, packaging, delivery, and more.

Implementation of IoT-based Inventory Management

IoT-based systems are also called perpetual systems. It is an inventory accounting method that uses real-time tracking. Let’s dive into its uses in the order-fulfillment process.

-

Track carts and forklifts

With real-time asset tracking, IoT systems know the exact location of the forklifts. Therefore, if the two of them are crossing similar paths, an alert is generated, saving them from crashing. Additionally, the system keeps track of the frequency of their use. Hence, it saves time and cost as well. -

Detect Product Condition

Automated systems with the help of RFID tags provide information on variables like temperature and weather. This helps in keeping a check on product health. For example, if a product’s temperature doesn’t match the requirement, the system will automatically update the product’s status to damage. Hence, the staff doesn’t have to check every product in the inventory manually. -

Inventory status and position

With automated systems in place, it becomes easy to track inventory. In addition, the status, location, and other essential details are continuously updated in the databases, making it easy to track the product’s location and availability. -

Avoid Stockouts and Overstocking

Maintaining a balance between the minimum and maximum inventory levels can be challenging. IoT-based systems help you set a reorder point and a maximum point for the products. Whenever any product quantity hits the reorder point or the maximum limit point, an alert is generated, saving you from under and over-stocking. Moreover, you can automate the reordering of products, receiving orders, processing, and shipping. -

Preventive maintenance checks

The IoT-based systems help in preventing machine failures. Sensors keep track of the machine’s condition and keep it updated in the database in real-time. This allows the staff to keep the machinery up-to-date and get to know about the failure beforehand, saving time, labor, and costs.

To Conclude

IoT-based inventory management systems optimize inventory operations with real-time data. It is best for busin looking forward to expand and scale. However, establishing these systems for your warehouse can be expensive, and the best choice to avail the benefits of IoT-based systems is to outsource these tedious tasks. It helps you reduce lead time, avoid hidden costs, and fasten your services.

Automate Your Inventory Management with AppManufact

AppManufact provides IoT-based systems to enhance your operations. We have successfully implemented IoT-based inventory management systems and automated various other services at Fulfillment Hub USA. They offer 360-degree fulfillment solutions to businesses and individual e-commerce sellers.

With the implemented automated systems, they provide:

- Rapid fulfillment and delivery.

- Real-time tracking to their customers.

- Detailed insights for planning and forecasting.

You can also gain a competitive edge in the market by establishing automated systems with us. We provide you a customized solution according to your business requirements at an affordable price. Connect with our experts now to fasten your services and business operations with automation.

FAQs

What is IoT-based inventory management?

IoT-based inventory management is an automated system that reduces the workload for the warehouse staff by optimizing various operations with real-time data.

How is IoT-based inventory management better than a traditional system?

The IoT-based system provides real-time information about the inventory, its location, condition, and more. This automatically generated information helps fasten the inventory operations, provides updated databases, and reduces errors.

What is the main objective of employing IoT in inventory management?

The aim of employing IoT-based systems is to reduce errors and fasten the order-fulfillment process with real-time data.

What is IoT in the supply chain?

The Internet of Things (IoT) devices track and authenticate products and shipments using GPS and other technologies, which helps fasten the supply chain process.